Vision Inspection System

Home » Business Area » Inspection System » Vision Inspection System

Menu

Vision Inspection System

Menu

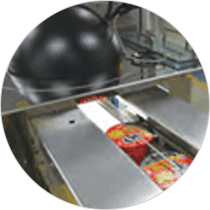

Intellisense VIS(Vision Inspection System) Series

This system is designed to automate visual inspections that have been conducted by inspectors by utilizing computer-based

camera imaging technologies. The system is applicable to a wide range of services, including product categorization,

impurity detection, omission test, and packaging inspection.

Nongshim engineering provides customized system satisfying customer's requirements perfectly.

Date stamp inspection

- · Date stamp inspection (OCR,OCV)

- · Package inspection

Product classification

- · Recognition of Box design recognition

- · Bar code inspection

Impurity inspection

- · Carbide inspection

- · Impurity inspection

Omission inspection

- · Content omission inspectionn

- · Package type inspection

Faulty package inspection

- · Faulty package inspection

- · Faulty cap-lead sheet inspection

System configuration

System configuration

System configuration

- Camer : black and white and color / area scan, line scan

- Lightin : LED lighting (Differentiated by inspected objects)

- Industrial computer

- Touch display

- Control panel

- System frame : customized for work sites

- Reject system : customized for work sites

- Inspection speed : Max 100m/min

- Power : AC220V (Single phase)

System features

System features

- Carrying out complex inspections simultaneously at high-speed line through multiprocessing

- Ease of use with simple and instinctive interfaces (Touch screen and keyboard)

- Supporting additional functions

- – Display of operation status and history (Operation message, alarm history, error notification, statistics of handled products)

- – Record inspection video and copy data through USB memory devices

- – Log management and report (excel) functions for inspected/abnormal products

- – Warning sound and light to nofity faulty product detection

- – Privilege management for admin and operators

- This system can meet customer needs by applying common inspection system

- Multiple lines can be inspected with single device(Max 4 lines per device)

- Facility control fuction for pre/post processing (only applied for devices provide control interfaces)